"Highlander-Datsuns are Forever" (jamesbowland)

"Highlander-Datsuns are Forever" (jamesbowland)

08/03/2017 at 13:14 ē Filed to: None

0

0

11

11

"Highlander-Datsuns are Forever" (jamesbowland)

"Highlander-Datsuns are Forever" (jamesbowland)

08/03/2017 at 13:14 ē Filed to: None |  0 0

|  11 11 |

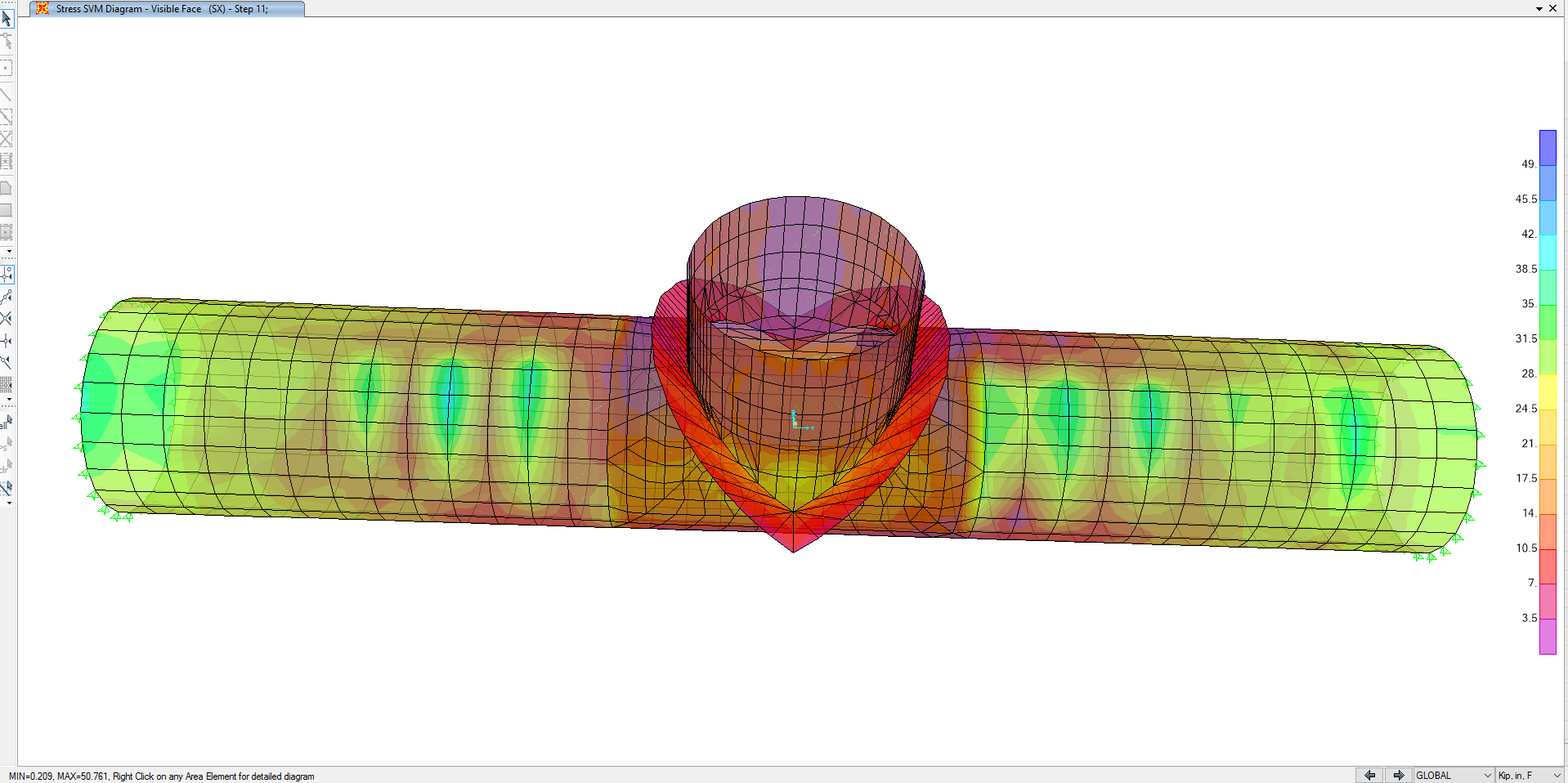

Stressing out here. 54" x 54" Tee joint.

For Sweden

> Highlander-Datsuns are Forever

For Sweden

> Highlander-Datsuns are Forever

08/03/2017 at 13:18 |

|

Is that a fine enough mesh at the joint?

MonkeePuzzle

> Highlander-Datsuns are Forever

MonkeePuzzle

> Highlander-Datsuns are Forever

08/03/2017 at 13:27 |

|

I can see the root cause of all the stress

Highlander-Datsuns are Forever

> For Sweden

Highlander-Datsuns are Forever

> For Sweden

08/03/2017 at 13:29 |

|

I think those are just lines to make the object look solid.

It should look like this when done:

Highlander-Datsuns are Forever

> MonkeePuzzle

Highlander-Datsuns are Forever

> MonkeePuzzle

08/03/2017 at 13:31 |

|

That crotch plate is essential for preventing the pipe from tearing apart under pressure.

MonkeePuzzle

> Highlander-Datsuns are Forever

MonkeePuzzle

> Highlander-Datsuns are Forever

08/03/2017 at 13:39 |

|

tee hee hee, crotch plate

yeah girls, my crotch plate is a love heart *awkwardest wink*

RamblinRover Luxury-Yacht

> For Sweden

RamblinRover Luxury-Yacht

> For Sweden

08/03/2017 at 13:45 |

|

FEA mesh size is srs bsns

Highlander-Datsuns are Forever

> RamblinRover Luxury-Yacht

Highlander-Datsuns are Forever

> RamblinRover Luxury-Yacht

08/03/2017 at 14:00 |

|

SRS biz, is srs biz yo.

BaconSandwich is tasty.

> Highlander-Datsuns are Forever

BaconSandwich is tasty.

> Highlander-Datsuns are Forever

08/03/2017 at 14:15 |

|

Huh. Interesting. I guess I do nít know much about pipes (or engineering for that matter). How does the crotch plate reduce stress? is it internal pressure that would cause it to burst, or is some outside force crushing in?

TheTurbochargedSquirrel

> Highlander-Datsuns are Forever

TheTurbochargedSquirrel

> Highlander-Datsuns are Forever

08/03/2017 at 14:26 |

|

FEAs are fun. What kind of forces are you testing? Pressure?

Highlander-Datsuns are Forever

> TheTurbochargedSquirrel

Highlander-Datsuns are Forever

> TheTurbochargedSquirrel

08/03/2017 at 14:35 |

|

In this situation the pipe is being pushed down a hill due to a land slide. The actual working pressure is about 100 psi, which is really low for this material which will be 1" thick welded steel pipe.

Highlander-Datsuns are Forever

> BaconSandwich is tasty.

Highlander-Datsuns are Forever

> BaconSandwich is tasty.

08/03/2017 at 14:38 |

|

When you cut a huge hole in the side of the pipe it looses itís hoop strength so you need to reinforce the outlet with the crotch plate. The crotch plate keeps the pipe from collapsing due to static loading from soil cover or live load due to cars and trucks.